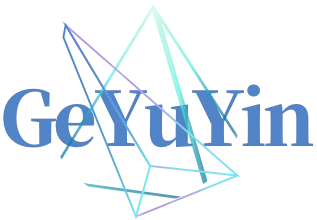

IMG_4617-JCR-10US

- Commodity name: IMG_4617-JCR-10US

Category:

Composition Item Technical parameters Product conditions Maximum diameter of product (MM) Φ103 Size of product bottle mouth (MM) Φ18 ~ Φ38 Maximum height of product (MM) <340

Keyword: Blow Molding Machine、Filling Machine

Product Details

Product Introduction

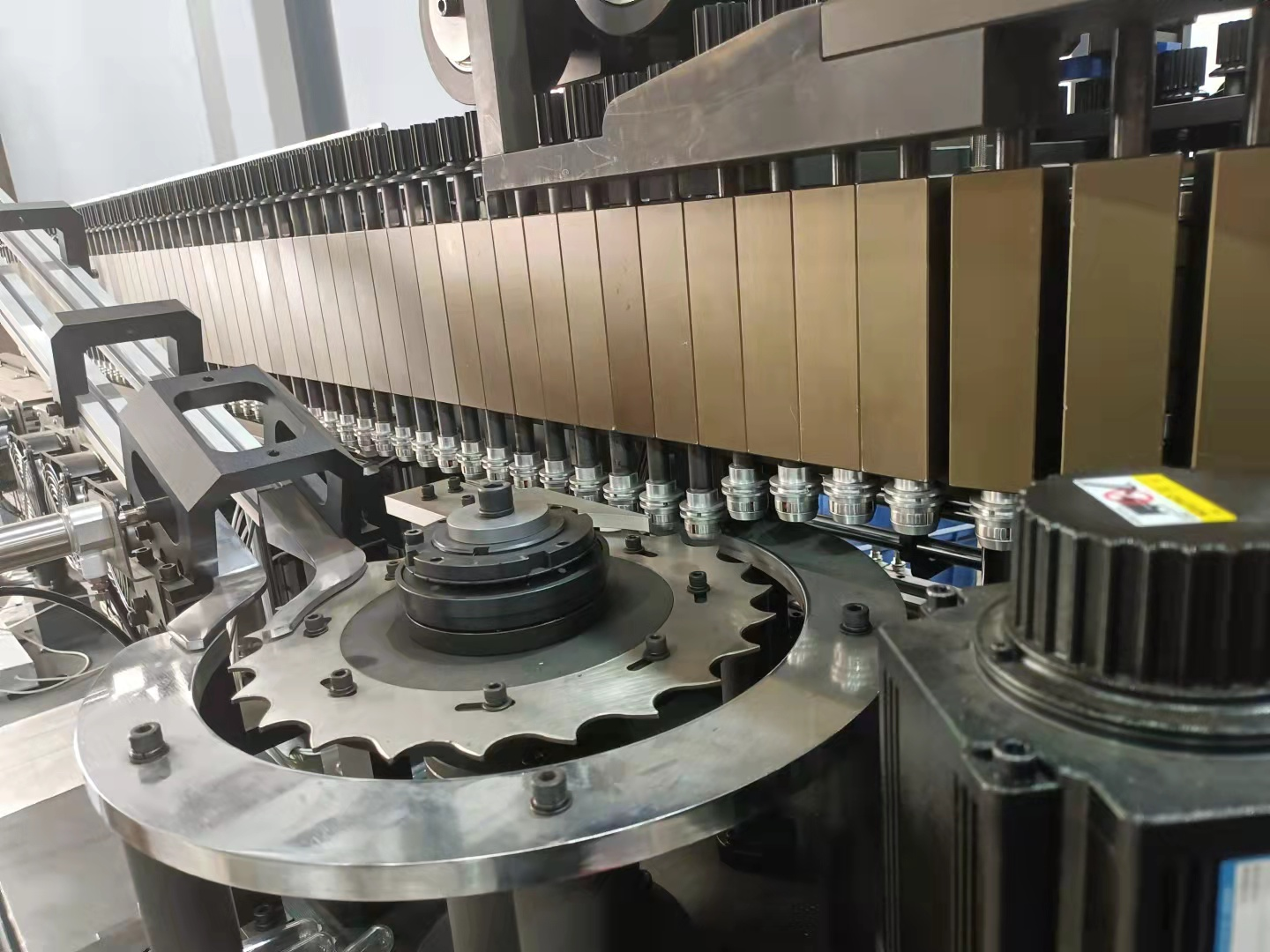

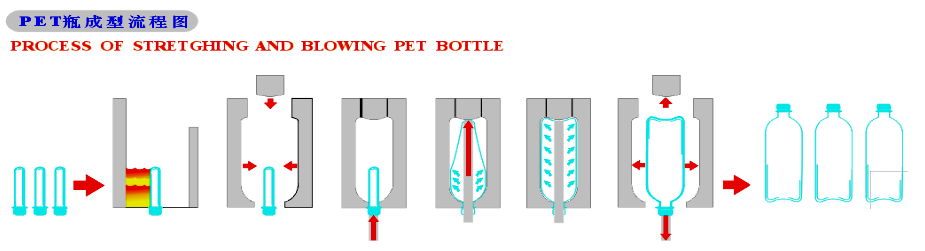

2.1.Embryo feeding system: adopting single-channel embryo feeding, star wheel embryo feeding, effectively solving the problem of jamming embryo and wear between embryos.

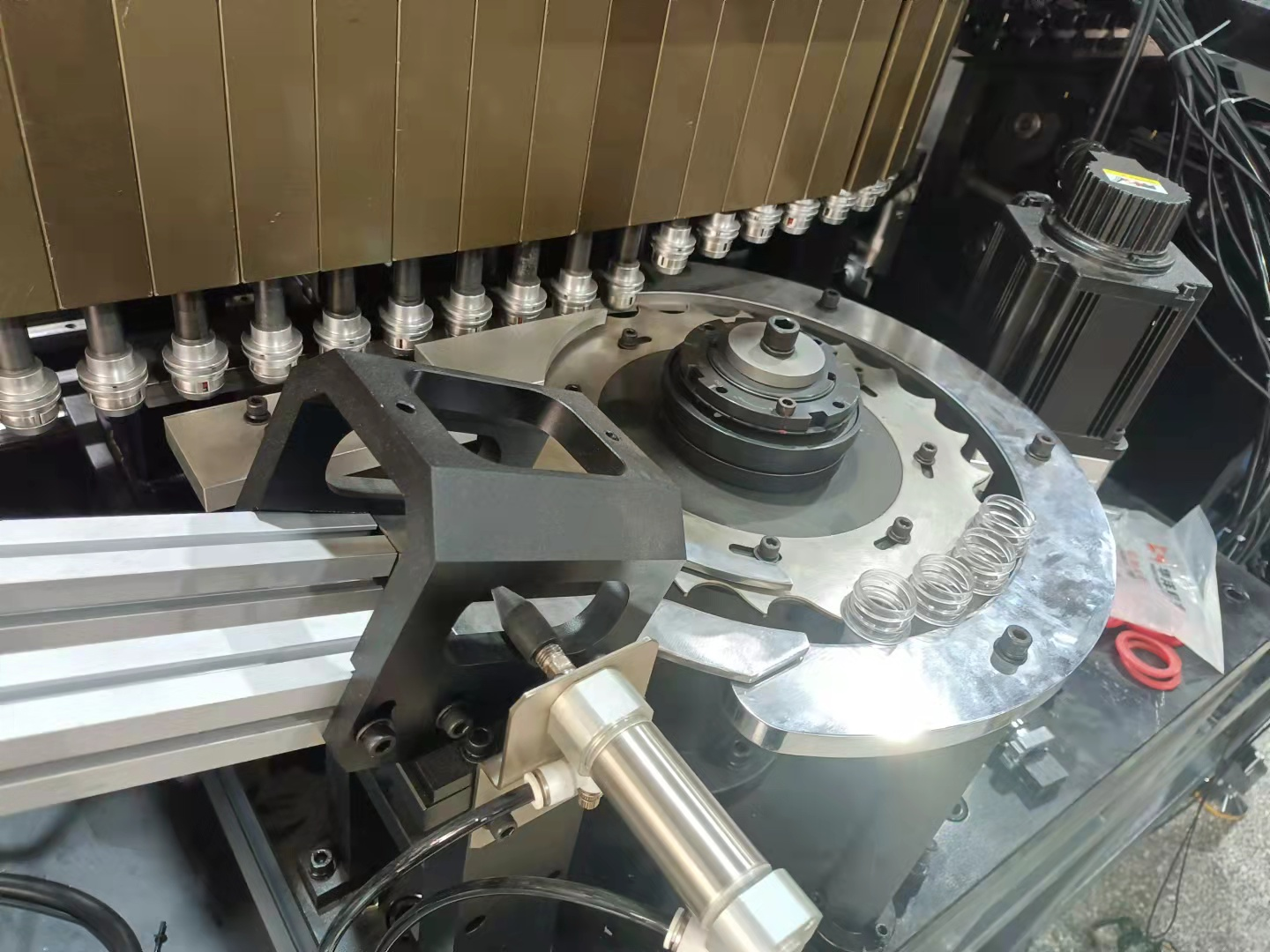

2.2.Male rotation system: adopting special chain, driven by servo motor, so that the heating unit in the movement of smooth, positioning

2.3 Heating system: adopting rotary blowing machine mode heating and conveying, which can reduce energy consumption and greatly improve the speed and quality of heating.

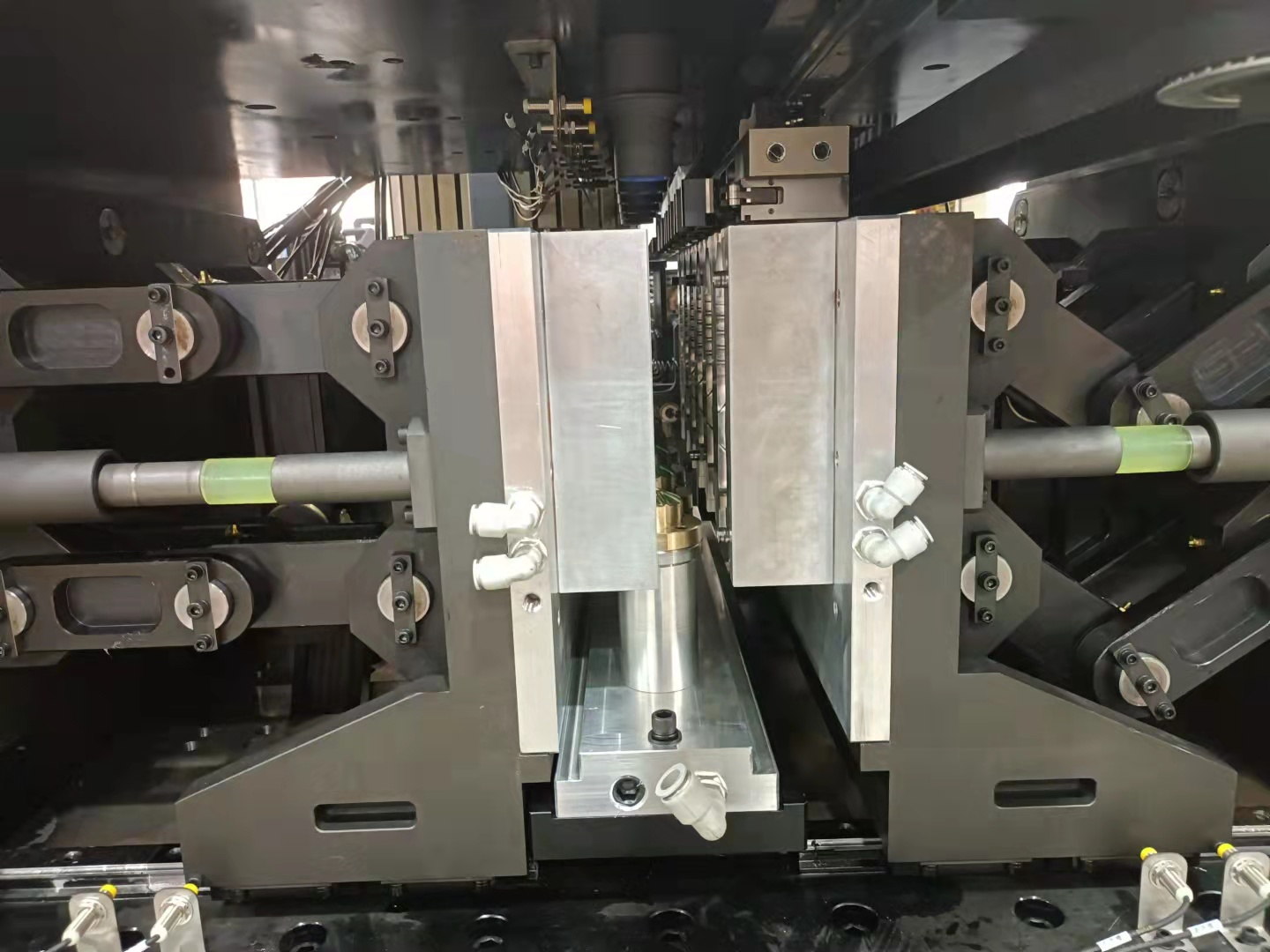

2.4.Mould system: adopting high-pressure mould locking technology, no expansion phenomenon, and the closing line is fine. The mould adopts drawer type structure, with four fixed tie rods positioned on the back plate of the mould, which can be easily replaced within half an hour.

2.5. Pulling and blowing system: one blowing, two blowing air cycle time can be adjusted, according to the customer's different tube embryo and different bottle type each pull rod can be adjusted individually, high flexibility.

2.6 Electric control system: pneumatic and electrical components are adopted international famous brand, touch screen control system is easy to operate, with perfect monitoring and sensing settings, with fault diagnosis function, automatic calculation report function, mastering the production efficiency of each class.

2.7. Cooling/freezing water circulation system: there is a cooling water channel under the heating box, when the bottle embryo is heated, the cooling water channel is used to block the heat of the lamp and protect the teeth from deformation. The chilled water leads to the moulds, cooling the moulds quickly and improving the efficiency of the whole machine capacity.

List of equipment parameters

|

Composition |

Item |

Technical parameters |

|

Product conditions

|

Maximum diameter of product (MM) |

Φ103 |

|

Size of product bottle mouth (MM) |

Φ18 ~ Φ38 |

|

|

Maximum height of product (MM) |

<340 |

|

|

Maximum height of suitable embryo tube (MM) |

<165 |

|

|

Mould closing stroke (MM) |

125 |

|

|

Bottom mould stroke (MM) |

50 |

|

|

Bottle pitch (MM) |

110 |

|

|

Production capacity (bottle/hour) |

1000BPH(1.5L) |

|

|

Production capacity (bottle/hour) |

14500BPH(550ML) |

|

|

Number of mould cavities |

6 |

|

|

Heating section |

Heating unit |

6 |

|

Number of heating lamp layers |

8 |

|

|

Number of germ tube holders (pcs) |

156 |

|

|

Electrical parameters

|

Voltage |

380V |

|

Frequency |

50/60Hz |

|

|

Used power |

30-40kw/h |

|

|

Installed power |

118kw |

|

|

Gas source (High pressure gas consumption depends on PET bottle volume) |

Low pressure compressed air pressure |

1Mpa |

|

Low pressure compressed air consumption |

1.0m3/min |

|

|

High pressure compressed air pressure |

3.0Mpa |

|

|

High pressure compressed air consumption |

12.0m3/min |

|

|

|

Pressure |

2-4bar |

|

Cooling water |

Flow rate |

6m3/h |

|

Cooling water (water temperature ≤18℃) |

Main machine\heater\electronic control box, etc. |

Approx. 7.5t |

|

Weight |

Main machine(L×W×H) |

5000mm×2300mm×2900mm |

|

Embryo Machine(L×W×H) |

2950mm×2120mm×3200mm |

Enquire Now

We will contact you within one working day. Please pay attention to your email.